Let’s explore the different types of low-slope roofing systems commonly used in residential and commercial construction. These systems are designed to efficiently shed water on roofs with minimal slope. Here are some key options:

Ethylene Propylene Diene Monomer (EPDM):

- EPDM roofing is a synthetic rubber membrane.

- Known for its durability, flexibility, and resistance to UV radiation.

- Commonly used for flat or low-slope roofs.

- Life expectancy: 20 to 30 years1.

Metal and Architectural Sheet Metal:

- Metal roofs, including standing seam panels, are suitable for low-slope applications.

- Durable, fire-resistant, and energy-efficient.

- Available in various materials such as steel, aluminum, and copper.

- Life expectancy: 40 to 70 years or more1.

Polyvinyl Chloride (PVC):

- PVC roofing membranes are single-ply thermoplastic sheets.

- Excellent chemical resistance and UV stability.

- Suitable for both low-slope and steep-slope roofs.

- Life expectancy: 20 to 30 years1.

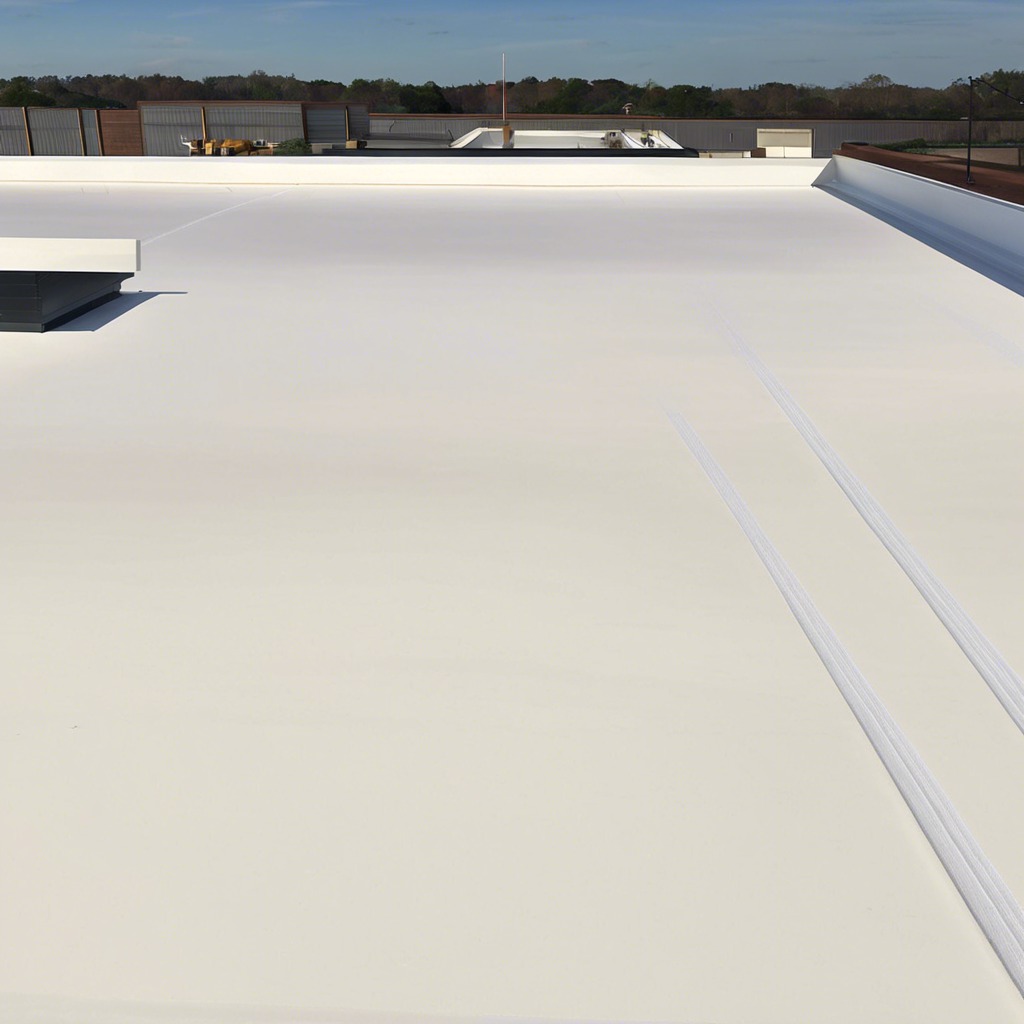

Thermoplastic Polyolefin (TPO):

- TPO roofing is another single-ply membrane.

- Energy-efficient and environmentally friendly.

- White TPO reflects sunlight, reducing cooling costs.

- Life expectancy: 20 to 30 years1.

Built-Up Roofing (BUR):

- BUR systems consist of multiple layers of asphalt-saturated felt or fiberglass.

- Alternating layers of bitumen and reinforcing fabric create a durable membrane.

- Commonly used on commercial buildings.

- Life expectancy: 20 to 30 years1.

Green Roof Systems:

- Green roofs involve planting vegetation directly on the roof surface.

- Provide insulation, reduce stormwater runoff, and improve air quality.

- Suitable for low-slope roofs with proper structural support.

- Life expectancy varies based on maintenance and plant health.

Remember that proper installation and maintenance play a crucial role in maximizing the lifespan of any roofing system. Consult with roofing professionals to determine the best solution for your specific needs. 🏠🌟